Print the Mask

Summary

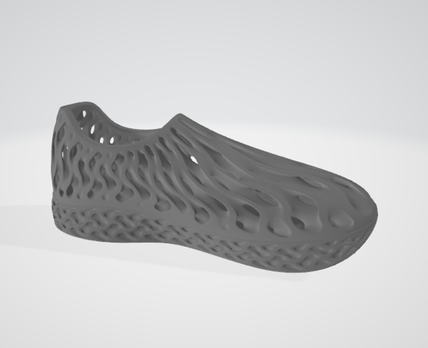

Making a basic mask for 3D printing is actually a pretty fun project, even if you’re just starting out. In this project I have used a Venetian mask design, it has the main features in the mask. It has holes on the side to add string or elastic to wear comfortably and holes for your eyes so you can see out of. If you are wearing the mask, I would recommend measuring it to make sure it all aligns to your face.

How you place the mask in your slicer is very important, and this model should be oriented vertically. This model has in-built support material and only needs a sufficiently sized Brim to ensure good bed adhesion. If the model has been scaled larger, it is important to check the supports will still be effective and add additional supports if necessary, prior to slicing.

Before i start printing, I clean my plate with isopropyl alcohol and sometimes add a light spray of 3D Printer Bed Adhesive to ensure good adhesion to the build plate. As this model is designed to have a very small contact area to the build plate, this step is very important. The resolution I used is 0.2 and infill is left at the default of 15%.

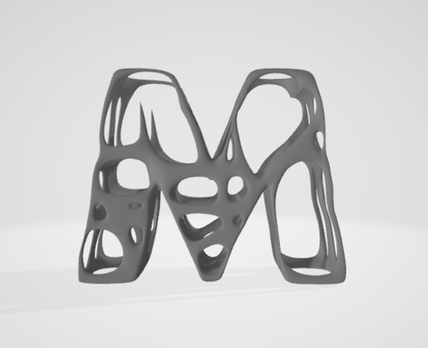

This project draws on a conceptual mark design originally shared on Thingiverse (thing:1084182).

Resources

Table of Contents

That's it! Well done on completing this project.

Share your finished work on social media and hashtag #Jaycar

Similar projects you may be interested in